PCS- 5000 Series Patch-clamp

Micromanipulation Systems

Total

Control in Patch Clamp Micromanipulation

Total control means your fingertip commands

are instantly and precisely converted to smooth and predictable pipette motion

without drift. Only Burleigh piezoelectric micromanipulators provide this

capability because we use the solid-state stability of piezoelectric (PZT)

technology.

PZT Technology

PZT actuators are solid ceramic structures that

expand under applied voltage. When controlled by Burleigh's drive electronics

and ergonomic control interface, extremely precise, fast, stiff and stable

positioning is easily achieved. The position of each PZT actuator is determined

by the DC voltage applied by the power supply. Burleigh's linear low-noise

electronics and cables are fully shielded and carefully grounded to produce

negligible interference of your recordings.

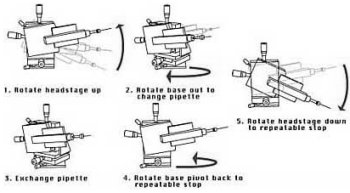

Simple Pipette

Exchange

Burleigh Instruments PCS-5000 Patch Clamp

Micromanipulators give you rapid, easy pipette exchange. Two pivot stages allow

the entire micromanipulator assembly to be rotated forward. In the forward

position, the headstage and pipette holder are very accessible, making pipettes

easy to remove and insert. After a new pipette is installed, the

micromanipulator assembly is rotated back to a precise and repeatable position. To

see an animation of the PCS-5000 click here.

Pipette Drift

of Less Than One Micron Per Hour

PZT actuators produce negligible internal thermal

drift. When external thermal changes are considered, a Burleigh system

contributes the same or less thermal position drift than other components such

as the microscope, mounting structure and headstage. With proper temperature

control, pipette drift of less than one micrometer per hour can be achieved. No

other micromanipulator has inherently lower drift than a Burleigh

Micromanipulator.

Components and Operational Features

|

PCS-520

Micromanipulator Assembly |

|

PCS-503

Axis Control Unit (ACU) |

|

PCS-PS-60

Power Supply |

Home | Prodotti | Lista rappresentate | Modulo Informazioni | News | Contatti